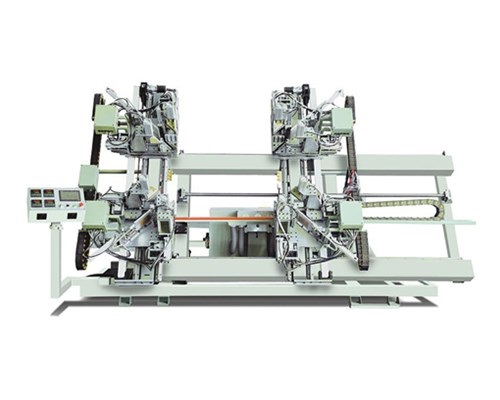

Features:

1. One

working cycle, one frame

2. Manual

measuring, moving and pneumatic brake. Auto operation after positioning.

Suitable

to

massive production with most of standard size window production

3. profile

fixture ordered separately can meet various height profiles' processing

requirement

4. Special

profile fixture is easy to change, for high corner strength and later

good cleaning

5. Imported

linear bearing system kept the running stable

6. Solid

machinery base and structure ensure long life service with satisfied

precision.

7. Special

“Know — How” technique keep the high corner strength

8. Advanced

“Parallel welding “technique is available for the VRWM3000P to achieve better

welding result.

9. Flexible

window type production in one cycle. VW3000P can not weld with mullion.

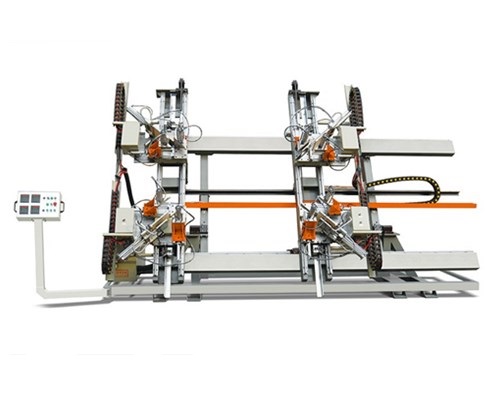

Parameters :

|

Air Pressure

|

0.5~0.8MPa

|

Air Consumption

|

150L/min

|

|

Input Power

|

11kw

|

Welding Height

|

20~180mm

|

|

Input Voltage

|

3N~380V 50HZ

|

Overall Dimension

|

5300×2100×2720mm

|

|

Welding

Width(Max)

|

150mm

|

Welding Range

|

450×450~1800×3000mm

|

|

|

|

weight

|

2600kg

|

Main accessory:

|

AC Contactor and Circuit Breaker

|

Schneider

|

Solenoid valve

|

SMC

|

|

Cylinder

|

JPC(FESTO Joint Venture Brand)

|

Air Filter Device

|

STNC

|

|

Electrical Button and Switcher

|

Schneider

|

Temperature Controller

|

Japan Omron

|

|

Linear bearing system

|

Linear (South Korean brand)

|

PLC

|

Japan Omron

|

Standard accessory:

|

Heating Plate

|

4pcs

|

Teflon Cloth

|

several

|

|

Air Gun

|

1pc

|

Complete tooling

|

1set

|

|

Certificate

|

1pc

|

Operation Manual

|

1pc

|

Русский

Русский English

English